Are you familiar with the Milkrun concept?

The Milkrun concept or Milkrun principle is a logistics concept. We briefly explain its meaning and functioning for today’s supply logistics.

Basic idea and historical origin of the Milkrun concept

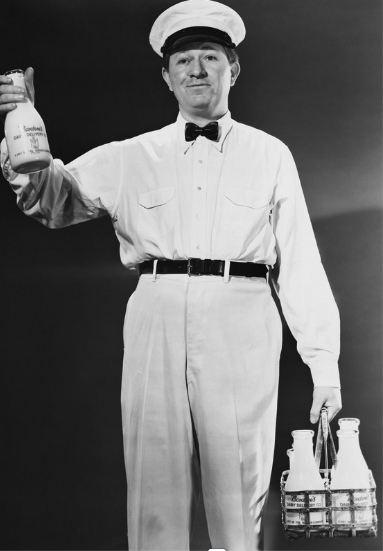

The concept of the Milkrun is based on the idea that only the material that has been consumed is replenished. It was inspired by the traditional milk boy in the USA and England, who only provided a bottle of milk if he could take an empty bottle with him. The milk supply was based on the available empties, which were then taken away again immediately. The replenishment cycle and route, similar to a bus timetable, are determined in advance. This is effective and saves time and costs in product distribution.

Whereas the milk boy was active in distribution logistics, the Milkrun concept is now used in supply and production logistics. Based on the existing consumption values, a supply cycle is defined on whose defined routes goods are delivered at specific times and at the same time goods and empties are picked up. In terms of effectiveness, cost savings and sustainability, the concept has once again gained in importance over the last few years.

The Milkrun concept: A delivery concept in materials management and supply logistics

The Milkrun concept is a method1 for optimising inter-company supply logistics and an important tool/principle of lean management to improve production runs.

In Milkrun logistics, a sender commissions one or more transport companies to call on different suppliers/customers one after the other in the form of a transport cycle. In this cycle, goods or empty goods can be delivered and taken back at the same time. The goal is to always have a full warehouse and as few empty trips as possible. The routes as well as the delivery times are firmly planned in this cycle, so that warehousing, e.g. at branches of a company, remains as low as possible.

Supply chains as well as production and assembly lines can be linked together in that way. This creates an automatic supply cycle via the material flow; this minimises manual or unplanned replenishment requirements. The definition of batch sizes, routes and schedules also reduces the complexity of the supply process, increases the utilisation of transports and at the same time reduces the transport costs in the company.

From the point of view of sustainability, the Milkrun is also a common concept, e.g. for the delivery/collection of pallets, which are used multiple times in this way. After all, the raw material wood is expensive and scarce due to numerous forest fires. In the meantime, the prices for Euro pallets have recovered and are between 6.70 and 9.65 euros2, depending on the quality class and whether new or used, but in the crisis year 2022 the price was between 19.50 and 23.00 euros.

The advantages of the Milkrun concept

- Lower transport costs due to short transport times and lower turnover of goods

- Better plannability in companies due to fixed time windows

- Lower capital commitment due to lower stock levels with simultaneous high availability of goods/products

- Disposal logistics are integrated into the supply process

- Sustainability through optimised transport routes and reuse of raw materials in packaging

The disadvantages and challenges of the Milkrun concept

- Time-intensive planning, especially with a large number of suppliers/customers: Here, transport volumes, delivery windows and driving times, among other things, must be taken into account.

- There must be a constant demand, e.g. for a company with many branches/customers.

- Suppliers must be able to deliver reliably

- Some factors, such as traffic obstructions and weather conditions, cannot be influenced.

- Only economically viable from a larger radius

Did you know that

… that India is the world’s largest producer of cow’s milk, ahead of the USA, with 106.09 million tonnes?3 In India, due to the high temperatures and lack of refrigerated vehicles, it is still common today for a milkman to deliver the milk. In countries like England and the USA, on the other hand, the milkman, which gave the concept its name, is almost no longer found in use.

Sources:

[1] Other logistical principles used are Kanban, FIFO, and single piece flow, among others.

[2] https://beschaffung-aktuell.industrie.de/rohstoffe/wie-entwickelt-sich-der-preis-fuer-europaletten/

[3] https://de.statista.com/statistik/daten/studie/37104/umfrage/milch-top-produzenten-weltweit-nach-menge/