Cómo las nuevas tecnologías están impulsando el cambio digital en el transporte y la logística

Beneficios y retos de la transformación digital: una mirada a España.

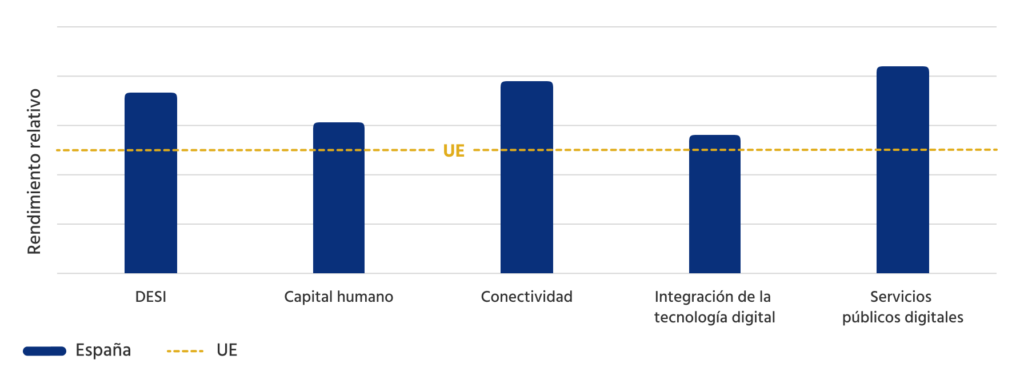

En los últimos años, España ha seguido un ritmo rápido en términos de digitalización en muchos sectores de la economía. Según el DESI (The Digital Economy and Society Index), España está entre los diez primeros países europeos en términos de digitalización en 2022. Las categorías del DESI «capital humano», «conectividad», «integración de las tecnologías digitales» y «digitalización de los servicios públicos» han evolucionado de forma especialmente positiva. Esto sitúa a España por encima de la media de la UE y en el 7º puesto de la clasificación de la UE (de los 27 países de la UE.1

El uso de las nuevas tecnologías ofrece un enorme potencial a las empresas de los sectores del transporte y la logística en particular y está impulsando el cambio digital en el país. Permiten a las empresas mejorar su eficiencia y sus procesos, reducir costes y ofrecer un servicio más rápido y fiable. Todos ellos son factores que influyen decisivamente en la competitividad de una empresa y en la satisfacción de sus clientes en un entorno de mercado globalizado.2

Transformación Digital España: Terreno fértil para el cambio digital

Gracias a su avanzado nivel de digitalización, España se encuentra en una posición ideal para aprovechar al máximo las oportunidades que ofrecen las nuevas tecnologías. Sin embargo, el país ya cuenta con una sólida base para el cambio digital en muchos ámbitos gracias a numerosos programas estratégicos y de apoyo:

- Infraestructura digital: 89% de España cubierta por cables de fibra (la UE está en el 50%). En cuanto al 5G, España ha pasado del 13% de cobertura en 2020 al 59% en 2021 y sigue mostrando una tendencia positiva.

- Intensidad digital: Según el DESI, las competencias digitales de las pymes están más de un 10% por encima de la media de la UE, tanto en conocimientos básicos como avanzados.

- Canales digitales: La economía española utiliza canales digitales para intercambiar información electrónicamente y para escalar su negocio.

La transformación digital aporta muchos beneficios, pero también plantea retos a las empresas. Nuestras preguntas más apremiantes: ¿Cuáles son los cambios para el sector de la logística y el transporte y cuáles son los mayores retos para las empresas de estas industrias?

Ejemplos de aplicación de las nuevas tecnologías en el transporte y la logística

Existen innumerables ejemplos de uso de las nuevas tecnologías en el transporte y la logística. Aquí resumimos los más importantes.

Aplicaciones móviles y plataformas de gestión: Optimizar y acelerar los procesos

Las plataformas de gestión ofrecen una visión general de toda la cadena de suministro y permiten optimizar los procesos en tiempo real. Por ejemplo, se puede planificar y seguir las rutas de las mercancías, controlar la utilización de la capacidad de máquinas y sistemas y gestionar los niveles de existencias. Las aplicaciones móviles contribuyen a una mayor eficiencia en los procesos de trabajo y permiten tiempos de respuesta más rápidos.

Blockchain: gestión inteligente de la cadena de suministro

La tecnología Blockchain garantiza una mayor transparencia y seguridad en la cadena de suministro. Funciona como un sistema de contabilidad centralizado y digital y proporciona un registro inalterable y seguro de todas las transacciones y movimientos de productos. Esto evita el fraude, minimiza la posibilidad de errores y garantiza la autenticidad de los productos. La información en tiempo real la hace indispensable para la gestión de la calidad y el seguimiento de los productos en particular.

Internet de las cosas (IoT): optimización del almacenamiento

Las instalaciones de fabricación (centros de producción) y los almacenes se benefician enormemente del IoT. Se pueden utilizar sensores para hacer un seguimiento de los niveles de existencias y controlar el flujo de mercancías. De este modo se pueden evitar cuellos de botella en el suministro y paradas inminentes de la producción en la industria manufacturera. Además de su uso en almacenes, el IoT también se utiliza para optimizar y planificar el tráfico y las rutas de transporte, un factor decisivo dentro de las cadenas de suministro.

Big data y análisis: Previsibilidad y minimización de costes

Los macrodatos constituyen la base del análisis de datos para predecir la demanda y ajustar los niveles de existencias. Esto reduce los costes de almacenamiento, ahorra recursos y garantiza que los productos estén disponibles cuando se necesitan. El big data también permite a las empresas comprender mejor las necesidades de sus grupos objetivo y desarrollar nuevas áreas de negocio basadas en los datos. Esto último es enormemente importante en vista de la fragilidad de las cadenas de suministro en los últimos años.

Robótica e inteligencia artificial (IA): La automatización aumenta la eficiencia

La robótica y la IA desempeñan un papel decisivo en la automatización de almacenes y centros de distribución para optimizar procesos y flujos de trabajo. Los robots autónomos pueden mover los productos de forma eficiente y reducir así la carga de trabajo de los empleados humanos. La IA garantiza que los productos estén disponibles y listos para su expedición. También acelera el proceso de picking y embalaje. Los costes operativos pueden reducirse mediante la automatización, por ejemplo al cargar y descargar camiones en las rampas de carga.

Impresión 3D: aceleración de los procesos de diseño y desarrollo

En el sector de la logística, la impresión 3D permite fabricar envases y embalajes personalizados de forma rápida y eficaz. En términos de sostenibilidad, esto reduce los costes de envasado y minimiza los residuos. La impresión 3D también puede utilizarse para crear prototipos y modelos de productos, lo que acelera los procesos de diseño y desarrollo al tiempo que reduce los costes.

Vehículos eléctricos y energía limpia para una mayor sostenibilidad

Customers are increasingly focussing on sustainability, and the transport and logistics industries are also trying to meet this demand. In order Los clientes se centran cada vez más en la sostenibilidad, y las industrias del transporte y la logística también intentan satisfacer esta demanda. Para reducir las emisiones de carbono y minimizar el impacto de estas industrias en el medio ambiente, es crucial el cambio a los vehículos eléctricos y la investigación en fuentes de energía limpias. La integración de las tecnologías de energías limpias en la logística incluye también la gestión de flotas. Las empresas buscan soluciones de transporte respetuosas con el medio ambiente, como camiones eléctricos y sistemas de carga alimentados por energía solar.

Drones y vehículos aéreos no tripulados: entregas de última milla

Los drones y los vehículos aéreos no tripulados se utilizan ahora con frecuencia para entregas de última milla. Evitan el tráfico rodado y pueden entregar paquetes más rápidamente, sobre todo en zonas de difícil acceso. Su uso es muy variado en todos los sectores: los drones vigilan instalaciones, inspeccionan infraestructuras y se utilizan para cartografiar.

Realidad aumentada (RA) y realidad virtual (RV)

La RV se utiliza para simular situaciones de formación, por ejemplo la conducción de camiones en condiciones meteorológicas extremas o la manipulación de mercancías delicadas. Esto aumenta la seguridad y la eficiencia, ya que los empleados reciben formación en un entorno controlado.

¿Cuáles son los retos de la transformación digital?

Superar estos retos requiere una planificación cuidadosa, una inversión estratégica en tecnología y una atención constante a la adaptación al entorno digital en constante cambio. Las empresas que superen estos retos estarán mejor posicionadas para seguir siendo competitivas en el sector de la logística y el transporte.

Aunque el nivel de digitalización de la economía española es alto, es necesario ponerse al día en el uso de nuevas tecnologías como el big data y las tecnologías en la nube para mantener el impulso del crecimiento. Ambas tecnologías son la base del éxito de la transformación digital en España, pero aún no se han introducido en las empresas españolas (el 99% son pymes) o los datos no se utilizan plenamente para optimizar los procesos. Como en muchos países de la UE, la falta de mano de obra con formación digital también está frenando la integración de las tecnologías digitales, especialmente en las pymes, que necesitan urgentemente trabajadores cualificados con conocimientos digitales.3

Aunque los canales y procesos están digitalizados al detalle, a menudo no están conectados en red ni optimizados para ampliar los modelos de negocio, crear experiencias personalizadas para los clientes y optimizar los procesos.4

Los mayores retos, y esto se aplica a todos los países de la UE, son: Integración de sistemas, ciberseguridad, costes iniciales, cambio cultural, educación y formación, escalabilidad, análisis de datos, visibilidad y trazabilidad y sostenibilidad.

En resumen: el uso de las nuevas tecnologías está cambiando la forma de entregar y gestionar los productos y, por tanto, toda la cadena de suministro. Los motores de la transformación digital son la eficiencia y la sostenibilidad. Las empresas que adopten y utilicen estas tecnologías tendrán más éxito en un mundo cada vez más conectado y automatizado.5

En el caso de España, puede decirse que el grado de digitalización de la economía española aumentó en cinco puntos porcentuales hasta alcanzar el 22% del PIB en 2022 y podría aumentar entre 1,5 y 2,5 puntos porcentuales al año hasta 2025, lo que podría mejorar la productividad de las PYME entre un 15 y un 25%.6 En conjunto, España puede mirar al futuro con optimismo. Ya se han sentado las bases de la infraestructura digital, la población y las empresas están alfabetizadas digitalmente y saben cómo utilizar las nuevas tecnologías para ampliar sus negocios y aumentar la eficiencia. Las cifras del DESI muestran que España ha mejorado enormemente en casi todas las categorías en los últimos dos o tres años. Esto demuestra que los programas de estímulo económico y las estrategias y campañas asociadas están funcionando, lo que seguirá impulsando positivamente la digitalización en el país.

Puede que también te interesen estos artículos:

Reforzando la resiliencia de las cadenas de suministro

Personal, digitalización y aumento de costes, los grandes retos del sector logístico

Cadenas de suministro seguras: los costes de transporte y logística como factor clave del éxito

El mcanismo de adjuste en frontera por carbono de la ue cbam lo que hay saber ahora

¿Conoces el concepto milk run?

El mercado español de paquetería ha demostrado ser a prueba de crisis

Referencias:

1) https://digital-strategy.ec.europa.eu/de/policies/desi-spain

2) https://www.logisticaprofesional.com/texto-diario/mostrar/4537184/nuevas-tecnologias-estan-impulsando-transformacion-digital-transporte-logistica

3) https://digital-strategy.ec.europa.eu/de/policies/desi-spain

4) https://blog.digitall.com/de/spotlight-spanien-digitaler-leader-aber-ohne-cloud#schwaechen

5) https://www.logisticaprofesional.com/texto-diario/mostrar/4537184/nuevas-tecnologias-estan-impulsando-transformacion-digital-transporte-logistica

6) https://www.eldiario.es/canariasahora/impulsa-startups/deutsche/die-digitale-transformation-in-spanien-erreicht-ihren-hoehepunkt_1_9708510.html